But read on and please learn from my mistakes!

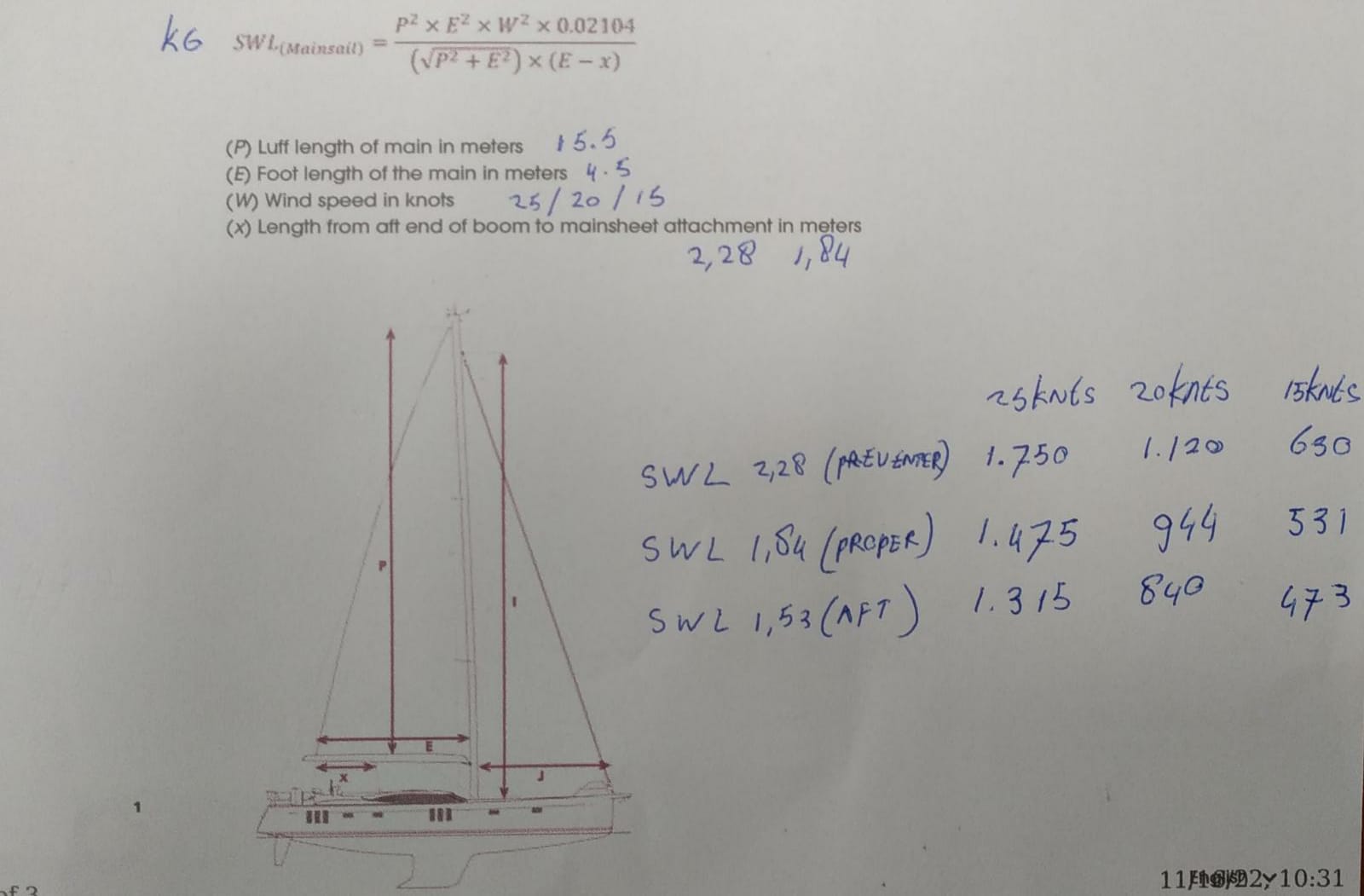

To avoid interference with the solar panels on the hard dodger the main sheet was attached to the FORWARD attachment and that is WRONG: the forward attachment is intended for the preventer ONLY.

A good welding job: the repair held almost 4 years and over 20.000 miles. Cracks developed and grew slowly over time. As the middle attachment point for the main sheet was no longer there the forward attachment point was used instead, which is WRONG.

But why?

Then our neighbour Mitch adviced us to go back to Queensway Gibraltar and see Pritchards Marine. They booked us in immediately.

Let’s hope we can close this chapter now with this last repair to the boom!